Products

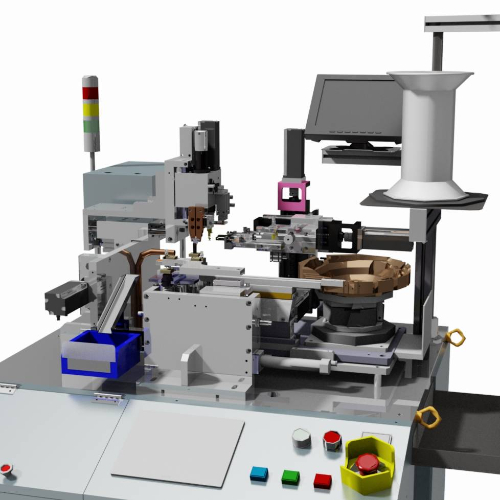

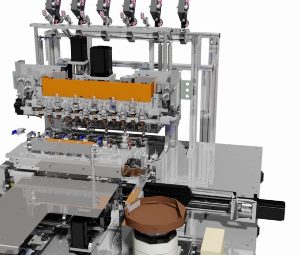

DSW-3024PN 24 Spindles Coil Winding Machine

October 19, 2020

FCW-01FC 1 Spindle Inductor Winding Machine with heater

October 19, 2020FCW-01PW 1 Spindle Inductor winding machine

Feature:

1. CNC 5 axles servo controller

2. Machine equips with automatic parts feeder to increase quantity capacity & reduce labor cost.

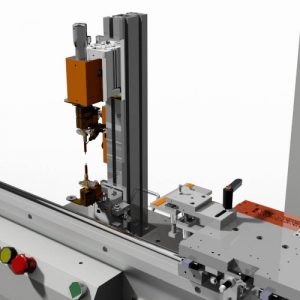

3. XYZθ axle runs with 100W servo motor moving quickly and precision.

4. End-Bobbin holding unit goes with main axle having accurate position to reduce wire broken.

5. Quickly change tooling design

6. Equip with quality tensioner controls winding quality.

7. High level language instruction, with 10″ touch panel program setting friendly.

8. Password feature to prevent program from modified by non-related person.

9. Simple structure, easy control, less failure, easy maintenance.

10. Wire dia. under 0.15mm, remain wire is fixed by welding unit ,wire dia. between 0.15~0.35mm, remain wire be cut by cutter.

| Controller | CNC 5axle control |

| Spindles | 1 spindle |

| Nozzle movement θ Axis X Axis Y Axis Z Axis |

360° 65mm 65mm 65mm |

| Wire dia. | ψ0.05~ψ0.35mm |

| Power supply | AC 220V ; 1ψ ; 50/60Hz 3KVA |

| Air pressure | 4~6kgf/cm2 |

| Machine size | 985(L)x990(W)x(H)1330mm(MAX) |

| Machine weight | 230kgs±10 |

| Inductor max size: | 3*3~8*8mm |

| Angle | 1° |

Product-related: CD core

Optional unit

*Conveyor: Servo type, Chain conveyor,

modular conveyor, belt conveyor

*PLC: Siemens, Schneider, Keyence,

Omron, Misubishi, Panasonic

*Any brand of Testing devices

*LASER device for marking, printing,

welding,copper wire stripping,TIW insulation wire removing

*Ink marking printer

*Mechanical robot pick and place mechanism,

*RFID reader + sensor, Remote control system,

*Internet Services Provides, SPSS data collection

Machine-related:

Automatic machine line, Pin inserting, Winding machine, Soldering machine, Spot welding machine, OEM machine, Testing machine, Assembly machine, Coil taping machine.